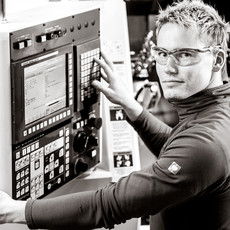

Martin D.

“The great thing about the company is that everyone knows each other. The hierarchies are flat. The communication paths are short. The boss is there when you need him.”

“After training as a cutting machine operator with a focus on turning technology, I was hired by Tittel. My tasks included independently setting up machines, writing and optimising programs and selecting and ordering tools. Eventually, there came a time when I wanted to pursue new professional paths. In 2016, I started working for a company as a field agent and helped around 350 companies to fit machines and tools.

Why did I decide to return to Tittel? Quite simply, the working conditions are great. What is special here is the orderly structure. Everything is neatly arranged – from the jobs to the machinery. And the cooperative spirit is just right. The great thing about the company is that everyone knows each other; the hierarchies are flat, the communication paths are short. And the boss is there when you need him. I get the impression this isn’t necessarily the case everywhere.

I’m currently working as a setter for the CNC sliding head automatic lathes. For the past year, I have also been guiding a trainee on his path through the company.

What do I like about the work? The variety. New machinery is constantly being added. We produce new parts almost daily. You’re always being asked to put your skills to the test. What I really enjoy is continually optimising the processing of components. For batch sizes of a few thousand units, it makes a substantial difference when getting the programming right can shorten the processing time by a few seconds.

I’d like to get my master’s degree in the coming years. But I’m thinking I’ll probably do it as a job-based qualification. It takes a bit longer, but it lets you maintain contact with the practical world. Machining is developing at a rapid pace. By taking time out, you lose touch with the machines – and of course with your colleagues as well.”